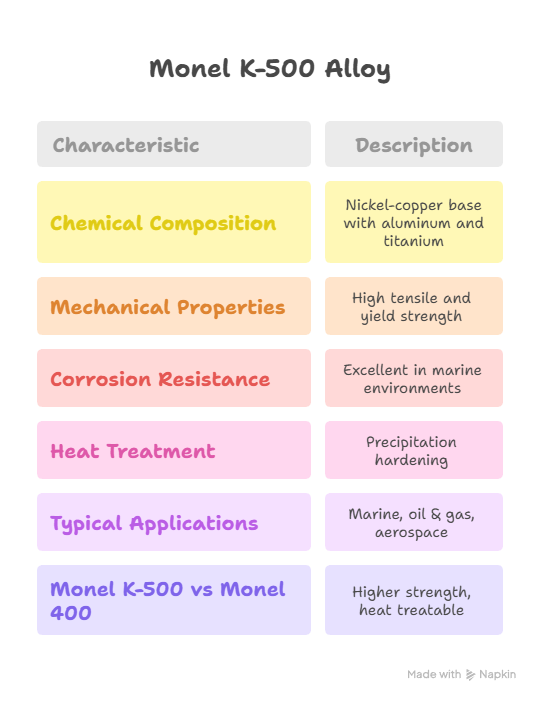

Monel K-500 is a precipitation-hardened nickel-copper alloy that combines the excellent corrosion resistance of Monel 400 with significantly higher strength and hardness. By adding aluminum and titanium to the nickel-copper base and applying heat treatment, Monel K-500 achieves superior mechanical performance while maintaining outstanding resistance to seawater, chemicals, and harsh marine environments. This unique balance makes it a preferred material for demanding structural and marine applications.

Chemical Composition of Monel K-500

The alloy’s composition is designed to enable precipitation hardening while preserving corrosion resistance.

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 63.0–70.0 |

| Copper (Cu) | 27.0–33.0 |

| Aluminum (Al) | 2.30–3.15 |

| Titanium (Ti) | 0.35–0.85 |

| Iron (Fe) | 2.0 max |

| Manganese (Mn) | 1.5 max |

| Carbon (C) | 0.25 max |

| Silicon (Si) | 0.5 max |

Mechanical Properties

Monel K-500 offers much higher strength than standard Monel grades, especially after aging treatment.

| Property | Typical Value |

|---|---|

| Tensile Strength | 960–1100 MPa |

| Yield Strength (0.2% offset) | 690–790 MPa |

| Elongation | 20–30% |

| Hardness | 28–35 HRC |

| Density | 8.44 g/cm³ |

Corrosion Resistance Characteristics

Monel K-500 retains excellent corrosion resistance similar to Monel 400, particularly in marine and chloride-rich environments.

| Environment | Performance |

|---|---|

| Seawater | Outstanding resistance |

| Salt Spray | Excellent |

| Acidic Solutions | Good to excellent depending on concentration |

| Alkaline Media | Excellent |

| Stress Corrosion Cracking | Highly resistant |

Heat Treatment and Strengthening

Unlike Monel 400, Monel K-500 can be precipitation hardened to achieve higher mechanical strength.

| Aspect | Description |

|---|---|

| Strengthening Method | Precipitation hardening |

| Key Elements | Aluminum and titanium |

| Heat Treatment | Solution annealing followed by aging |

| Result | Significant increase in yield and tensile strength |

Typical Applications of Monel K-500

The combination of high strength and corrosion resistance makes Monel K-500 suitable for critical components.

| Industry | Applications |

|---|---|

| Marine Engineering | Propeller shafts, pump shafts, seawater fasteners |

| Oil & Gas | Valve components, drill collars |

| Aerospace | High-strength fasteners and springs |

| Chemical Processing | Corrosion-resistant mechanical parts |

Monel K-500 vs Monel 400

Although both alloys share similar corrosion resistance, their strength levels differ significantly.

| Property | Monel K-500 | Monel 400 |

|---|---|---|

| Strength | Much higher | Moderate |

| Heat Treatable | Yes | No |

| Corrosion Resistance | Excellent | Excellent |

| Cost | Higher | Lower |

Related Questions

1. What is Monel K-500 used for?

It is commonly used for marine shafts, fasteners, oil and gas components, and aerospace parts requiring high strength and corrosion resistance.

2. Is Monel K-500 stronger than Monel 400?

Yes, Monel K-500 is significantly stronger due to precipitation hardening while maintaining similar corrosion resistance.

3. Can Monel K-500 be used in seawater?

Yes, it performs exceptionally well in seawater and chloride-rich environments, making it ideal for marine applications.