Monel metal is a group of nickel alloys primarily composed of nickel (typically 60–70%) and copper, along with small amounts of iron, manganese, carbon, and other trace elements. Known for its excellent corrosion resistance, high strength, and good weldability, Monel metal is widely used in marine engineering, chemical processing, aerospace, and other demanding environments. It combines the corrosion resistance of nickel with the toughness and strength of copper, making it ideal for applications exposed to harsh conditions.

Composition of Monel Metal

| Element | Typical Percentage (%) | Role |

|---|---|---|

| Nickel | 60–70 | Main corrosion resistant and strength element |

| Copper | 28–34 | Enhances toughness and corrosion resistance |

| Iron | 2.5–3.5 | Improves strength and hardness |

| Manganese | 1.0–2.0 | Improves hot working properties |

| Carbon | ≤0.3 | Limits carbide formation |

Key Properties of Monel Metal

Corrosion Resistance: Monel excels in resisting seawater, acids (such as sulfuric and hydrofluoric acid), and alkalis, outperforming many stainless steels in harsh chemical environments.

Mechanical Strength: It offers high tensile strength and good fatigue resistance, making it suitable for structural components.

Temperature Stability: Maintains strength and corrosion resistance in temperatures ranging from cryogenic to about 600°C.

Weldability and Fabrication: Monel alloys can be welded and formed easily, allowing for versatile manufacturing.

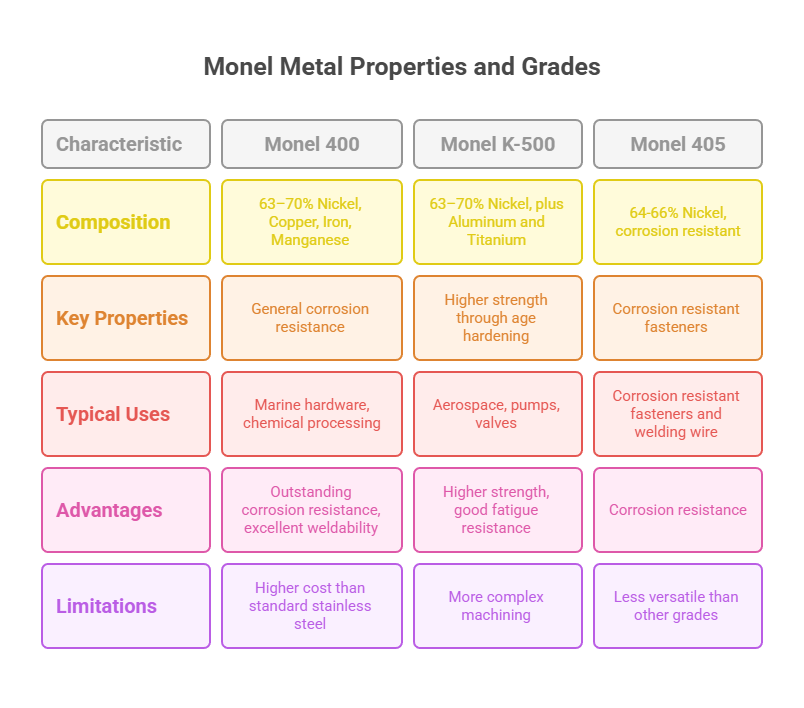

Common Grades of Monel

| Grade | Nickel Content (%) | Typical Uses |

|---|---|---|

| Monel 400 | 63–70 | General corrosion resistance, marine hardware, chemical processing |

| Monel K-500 | 63–70 | Higher strength through age hardening, aerospace, pumps, valves |

| Monel 405 | 64–66 | Corrosion resistant fasteners and welding wire |

Applications of Monel Metal

| Industry | Application | Reason for Use |

|---|---|---|

| Marine | Propeller shafts, pump shafts, seawater valves | Excellent seawater corrosion resistance |

| Chemical Processing | Heat exchangers, chemical reactors | Resistance to acids and alkalis |

| Aerospace | Fasteners, turbine blades | High strength and temperature resistance |

| Oil and Gas | Valves, pumps, connectors | Corrosion resistance to sour gas and sea environments |

Advantages and Limitations of Monel Metal

Advantages: Outstanding corrosion resistance, high strength, good fatigue and impact resistance, excellent weldability.

Limitations: Higher cost than standard stainless steel, less resistance to oxidizing acids, relatively heavy compared to aluminum alloys.

Related Questions and Answers

What is the difference between Monel 400 and Monel K-500?

Monel 400 is a standard corrosion-resistant alloy, while Monel K-500 has added aluminum and titanium for age hardening, resulting in higher strength suitable for aerospace and high-stress applications.

Is Monel metal magnetic?

Monel is generally non-magnetic due to its nickel-copper composition, although slight magnetic properties may appear after cold working.

Can Monel be welded easily?

Yes, Monel alloys have good weldability using common welding methods such as TIG and MIG, with proper control of heat input to avoid cracking.