Waspaloy is a high-performance, nickel-based superalloy known for its exceptional strength, corrosion resistance, and stability at elevated temperatures. It was developed primarily for aerospace and gas turbine applications where components are exposed to extreme heat and stress. Waspaloy is widely used in aircraft engines, industrial gas turbines, and other high-temperature machinery due to its ability to retain mechanical properties under demanding conditions.

Chemical Composition

Waspaloy is mainly composed of nickel (50–60%), chromium (18–21%), cobalt (12–15%), molybdenum (3–5%), and small amounts of titanium (1–2%) and aluminum (0.4–1%). This precise alloying combination allows Waspaloy to form austenitic matrix reinforced with gamma prime (γ’) precipitates, which are responsible for its high strength at elevated temperatures.

Mechanical Properties

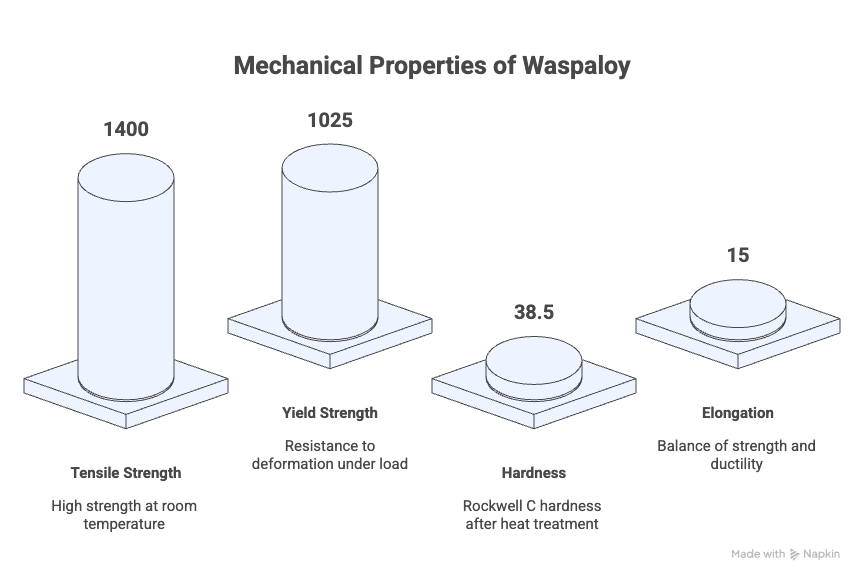

Waspaloy exhibits excellent mechanical properties, particularly at high temperatures:

- Tensile Strength: 1,300–1,500 MPa at room temperature, remaining high at temperatures up to 700–750°C.

- Yield Strength: 950–1,100 MPa, providing resistance to deformation under load.

- Fatigue Resistance: Outstanding resistance to cyclic stress, making it ideal for rotating components.

- Hardness: Rockwell C 35–42 after proper heat treatment.

- Elongation: 10–20%, balancing strength with ductility.

Thermal Properties

Waspaloy maintains stability under high-temperature conditions, essential for gas turbine and jet engine applications:

- Operating Temperature: Can perform effectively up to 700–750°C.

- Melting Point: Approximately 1,340–1,380°C.

- Thermal Expansion: Around 13.0 × 10⁻⁶ /°C, ensuring dimensional stability under temperature changes.

- Thermal Conductivity: Relatively low, helping reduce thermal fatigue.

Corrosion and Oxidation Resistance

Waspaloy offers strong resistance to oxidation and corrosion in high-temperature and oxidizing environments. Its high nickel and chromium content forms a protective oxide layer that shields the alloy from degradation. It also resists hot corrosion, making it suitable for marine and chemical processing applications.

Applications

Due to its high-temperature strength and corrosion resistance, Waspaloy is widely used in critical components such as:

- Aircraft engine parts: turbine blades, discs, seals, and fasteners.

- Industrial gas turbines: combustor parts, blades, and shafts.

- High-temperature chemical equipment: pumps, valves, and heat exchangers.

- Aerospace structural components that require both high strength and thermal stability.

Related Questions

Is Waspaloy suitable for high-temperature applications? Yes, it maintains strength and stability at temperatures up to 700–750°C.

Is Waspaloy magnetic? Generally no, Waspaloy is non-magnetic in its standard austenitic form.

How does Waspaloy compare to Inconel 718? Waspaloy has higher cobalt content and slightly better high-temperature strength, while Inconel 718 is more widely used and has easier weldability.