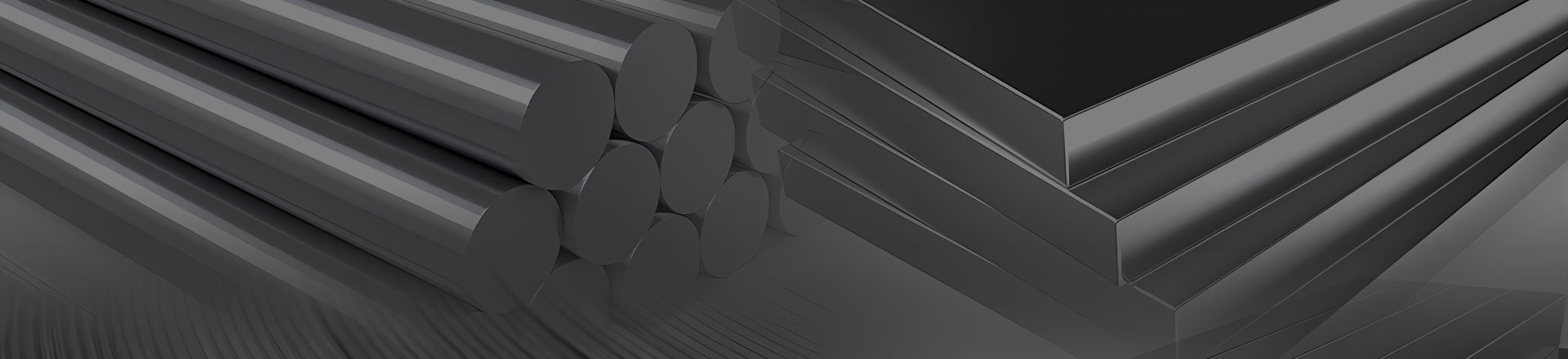

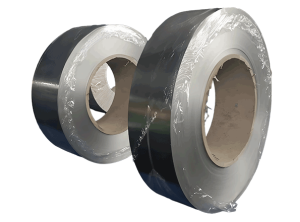

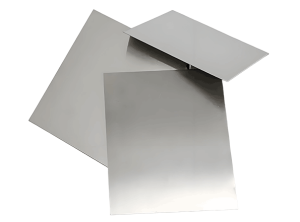

Inconel 600 Strip

- Strip Thickness:0.01 mm (0.00039 in) – 1 mm (0.0394 in); custom thickness available

- Strip Width:Max 500 mm (19.685 in); custom width available

- Delivery Condition:Solution Annealed, Annealed, Full Hard, Half Hard, Age Hardened; customized mechanical properties available

- Surface Condition:Pickled, Sandblasted, Polished, Mirror Finish; high finish available for premium applications

E-mail:[email protected]

We’re here to help:Easy ways to get the answers you needInconel 600 Strip

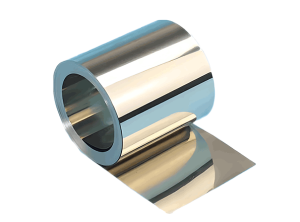

DescriptionInconel 600 strip is a nickel-chromium-iron alloy known for its excellent corrosion resistance, high-temperature strength, and outstanding oxidation resistance. It performs well in environments containing high heat, steam, and corrosive chemicals, maintaining stability from cryogenic temperatures up to about 1090°C (2000°F).

The alloy provides exceptional resistance to chloride stress corrosion cracking, oxidation, and carburization, making it suitable for heat-treating equipment, chemical processing, aerospace components, and nuclear engineering applications. Inconel 600 strip also offers good formability, weldability, and mechanical toughness across a wide temperature range.

We supply Inconel 600 strips in various thicknesses, widths, and tempers, available in annealed or cold-rolled conditions to meet specific industrial requirements.

Inconel 600 Strip

Chemical Compositions| Nickel (Ni) | 72% min |

| Chromium (Cr) | 14-17% max |

| Iron (Fe) | 6-10% |

| Carbon (C) | 0.15% max |

| Sulfur (S) | 0.015 max |

| Manganese (Mn) | 1% max |

| Silicon (Si) | 1.5-4% |

| Manganese (Mn) | 1.5% max. |

| Silicon (Si) | 0.5% max |

| Copper (Cu) | 0.5% max |

Inconel 600 Strip

Prices| Thickness | Width | Price in China (USD/kg) | Global Price (USD/kg) |

|---|---|---|---|

| 0.05 mm | 200–300 mm | 32–36 | 34–40 |

| 0.10 mm | 200–300 mm | 30–34 | 32–38 |

| 0.20 mm | 250–400 mm | 28–32 | 30–36 |