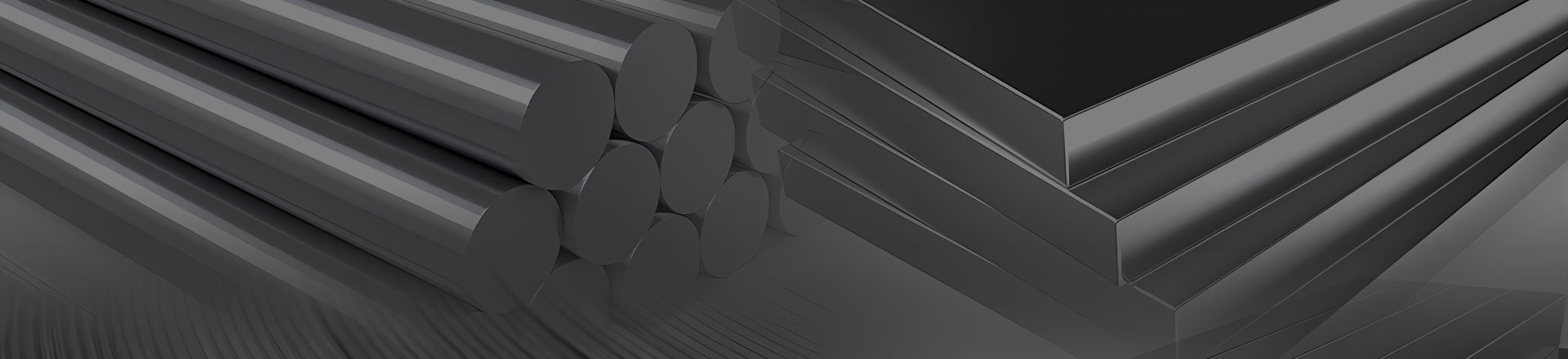

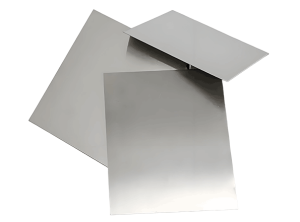

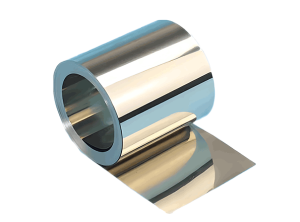

Inconel 625 Sheets

- Cold Rolled Plate Thickness:1 mm (0.0394 in) – 3 mm (0.118 in); high precision, suitable for demanding applications

- Cold Rolled Plate Width:Max 1500 mm (59.055 in); custom width available

- Cold Rolled Plate Length: Max 3 m (118.110 in); custom cutting available

- Hot Rolled Medium Plate Thickness:4 mm (0.157 in) – 30 mm (1.181 in); suitable for heavy-load projects

- Hot Rolled Medium Plate Width:Max 2800 mm (110.236 in); custom width available

- Hot Rolled Medium Plate Length :Max 12 m (472.441 in); suitable for large-scale processing

- Delivery Condition:Solution Annealed, Annealed, Full Hard, Half Hard, Age Hardened; customized mechanical properties available

- Surface Condition:Pickled, Sandblasted, Polished, Mirror Finish; high finish available for premium applications

E-mail:[email protected]

We’re here to help:Easy ways to get the answers you needInconel 625 Sheets

DescriptionInconel 625 sheet is a nickel-chromium-molybdenum alloy renowned for its exceptional corrosion resistance, high strength, and excellent fabricability. It performs reliably in a wide range of temperatures—from cryogenic to about 1000°C (1830°F)—and is particularly resistant to pitting, crevice corrosion, and oxidation.

This alloy’s outstanding resistance to a wide variety of severe corrosive environments, including seawater, acids, and oxidizing chemicals, makes it ideal for marine, chemical processing, and aerospace applications. Inconel 625 also maintains excellent fatigue and stress corrosion cracking resistance, ensuring long-term durability in both oxidizing and reducing conditions.

We supply Inconel 625 sheets in various thicknesses and sizes, available in annealed or solution-treated condition, customized according to customer specifications.

Inconel 625 Sheets

Chemical Compositions| Nickel (Ni) | 58% min |

| Chromium (Cr) | 20-23% |

| Iron (Fe) | 5.0% max |

| Molybdenum (Mo) | 8-10% |

| Niobium+Tantalum (Nb+Ta) | 3.15-4.15% |

| Carbon (C) | 0.1% max |

| Manganese (Mn) | 0.5% max |

| Silicon (Si) | 0.5% max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

| Aluminum (Al) | 0.4% max |

| Titanium (Ti) | 0.4% max |

| Cobalt (Co) | 1.0% max |

Inconel 625 Sheets

Prices| Specification (Thickness / Width) | China (USD/kg) | India (USD/kg) | Europe (USD/kg) | USA (USD/kg) | Remarks |

|---|---|---|---|---|---|

| Thin Sheets ≤ 3 mm | 45 – 55 | 50 – 60 | 60 – 75 | 65 – 80 | Cold rolled; used for chemical equipment and marine applications. Surface finish and certification affect price. |

| Medium Sheets 3 – 10 mm | 40 – 50 | 45 – 55 | 55 – 70 | 60 – 75 | Hot rolled or annealed; standard industrial applications. Width and temper affect pricing. |

| Thick Sheets ≥ 10 mm | 38 – 48 | 43 – 53 | 53 – 70 | 58 – 75 | Heavy plates; used for aerospace, marine, and chemical reactors. Larger sheets lower unit price but increase total cost. |

| Small Batch (< 500 kg) Surcharge | +10% ~ +25% | +10% ~ +25% | +15% ~ +40% | +15% ~ +45% | Small quantity or urgent orders increase cost; aerospace or certified sheets add extra premium. |