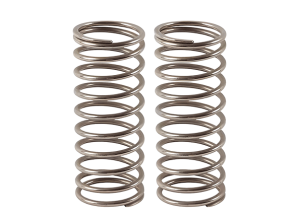

Inconel X-750 Springs

- Wire Diameter:0.1 mm (0.0039 in) – 15 mm (0.5906 in)

- Inner Diameter:1 mm (0.0394 in) – 200 mm (7.874 in)

- Outer Diameter:2 mm (0.0787 in) – 250 mm (9.843 in)

- Free Length:5 mm (0.1969 in) – 500 mm (19.685 in)

- Total Number of Turns:3-50 turns

E-mail:[email protected]

We’re here to help:Easy ways to get the answers you needInconel X-750 Springs

DescriptionInconel X-750 Springs are high-performance springs made from Inconel X-750, a nickel-chromium alloy known for its excellent strength, oxidation, and corrosion resistance at high temperatures. These springs are designed for use in demanding environments such as gas turbines, power generation, and aerospace applications, where reliability and durability are crucial.

High-Temperature Strength: Inconel X-750 Springs retain their strength and elasticity even at elevated temperatures, making them ideal for high-temperature applications such as turbine engines and heat exchangers.

Corrosion and Oxidation Resistance: The alloy’s resistance to oxidation and corrosion ensures a long service life in harsh environments, including exposure to sulfur, chloride, and other corrosive substances.

Excellent Fatigue Resistance: Inconel X-750 Springs offer superior fatigue resistance, making them suitable for high-stress applications where repeated loading and unloading are common.

Versatile Applications: Commonly used in aerospace, gas turbine engines, chemical processing, and other high-performance industries, these springs offer reliable performance under extreme conditions.

Inconel X-750 Springs are engineered for maximum reliability and performance in harsh, high-temperature environments. For more information on specifications or custom orders, feel free to contact our expert team.

Inconel X-750 Springs

Chemical Compositions| Nickel (Ni) | 70% min |

| Copper (Cu) | 14-17% |

| Iron (Fe) | 5-9% |

| Titanium (Ti) | 2.25-2.75% |

| Aluminum (Al) | 0.4-1% |

| Niobium+Tantalum (Nb+Ta) | 0.7-1.2% |

| Manganese (Mn) | 1% max |

| Silicon (Si) | 0.5% max |

| Sulfur (S) | 0.01% max |

| Copper (Cu) | 0.5% max |

| Carbon (C) | 0.08% max |

| Cobalt (Co) | 1% max |

Inconel X-750 Springs

Prices| Type / Specification | China (USD/kg) | India (USD/kg) | Europe (USD/kg) | USA (USD/kg) | Remarks |

|---|---|---|---|---|---|

| Compression Springs | 95 – 115 | 100 – 125 | 120 – 145 | 125 – 155 | Most common type; price depends on wire diameter, coil pitch, and temper condition. |

| Tension / Extension Springs | 100 – 120 | 105 – 130 | 125 – 150 | 130 – 160 | Additional cost for hooks or loops; requires precise stress-relief heat treatment. |

| Torsion Springs | 110 – 130 | 115 – 135 | 130 – 160 | 135 – 165 | Complex forming and winding; higher price for aerospace-grade or fine wire. |

| Custom Shape Springs | 120 – 145 | 125 – 150 | 140 – 170 | 145 – 175 | Special geometries, tight tolerances, or certification increase cost. |

| Small batch (< 200 pcs) surcharge | +10% ~ +25% | +10% ~ +25% | +15% ~ +40% | +15% ~ +45% | Prototype or sample orders require setup and tooling, adding extra cost. |