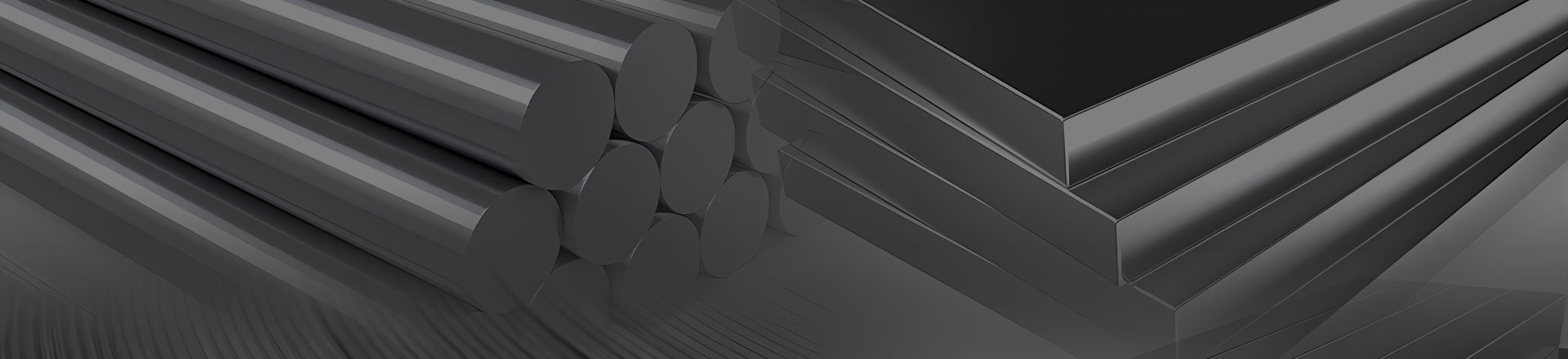

Nimonic 80A Bars

- Diameter:1 mm (0.0394 in) – 450 mm (17.717 in)

- Length:Up to 12 meters (472.441 in)

- Delivery Condition:Solution treated, annealed, age-hardened

- Surface Condition:Black, polished, turned, ground

- Shape:Round, square, hexagonal

E-mail:[email protected]

We’re here to help:Easy ways to get the answers you needNimonic 80A Bars

DescriptionNimonic 80A Bars are high-performance alloy bars made from Nimonic 80A, a nickel-based superalloy known for its excellent resistance to high temperatures, oxidation, and creep. These bars are widely used in critical applications such as gas turbines, jet engines, and other high-stress, high-temperature environments where durability and strength are crucial.

High-Temperature Resistance: Nimonic 80A Bars maintain exceptional strength and stability at elevated temperatures, making them ideal for use in turbine blades, combustion chambers, and other high-heat applications.

Corrosion and Oxidation Resistance: The alloy provides superior resistance to oxidation and corrosion, ensuring long-lasting performance in environments exposed to harsh conditions, including sulfur and other corrosive elements.

Creep Resistance: Nimonic 80A Bars are highly resistant to creep, a critical property for components that are subject to long-term stress and elevated temperatures, such as those found in aerospace and power generation industries.

Versatile Applications: Used extensively in aerospace, power generation, and chemical processing industries, Nimonic 80A Bars are ideal for manufacturing parts that require excellent high-temperature strength and durability.

Nimonic 80A Bars are engineered for maximum performance in the most demanding environments. For more details on technical specifications or custom orders, feel free to contact our expert team.

Nimonic 80A Bars

Chemical Compositions| Carbon (C) | 0.10 % max. |

| Chromium (Cr) | 18.0-21.0 % |

| Silicon (Si) | 1.0 % max |

| Copper (Cu) | 0.2 % max. |

| Iron (Fe) | 3.0 % max. |

| Manganese (Mn) | 1.0 % max. |

| Titanium (Ti) | 1.8-2.7 % |

| Aluminum (Al) | 1.0-1.8 % |

| Cobalt (Co) | 2.0 % max. |

| Boron (B) | 0.008 % max. |

| Zirconium (Zr) | 0.15 % max. |

| Lead (Pb) | 0.0025 % max. |

| Sulfur (S) | 0.015 % max. |

| Nickel (Ni) | Balance |

Nimonic 80A Bars

Prices| Specification (Diameter / Type) | China (USD/kg) | India (USD/kg) | Europe (USD/kg) | USA (USD/kg) | Remarks |

|---|---|---|---|---|---|

| ≤ 20 mm (Cold drawn / Precision ground) | 85 – 105 | 90 – 115 | 100 – 130 | 105 – 135 | Small diameters have higher machining costs; China usually more competitive for bulk orders. |

| 21 – 50 mm (Hot rolled / Forged bars) | 75 – 95 | 80 – 105 | 95 – 125 | 100 – 130 | Medium sizes are common; MOQ and delivery time affect price significantly. |

| ≥ 51 mm (Heavy forged / Cut from plate) | 70 – 90 | 75 – 105 | 95 – 130 | 105 – 140 | Large diameters have lower unit prices but higher total cost; machining and cutting extra. |

| Small batch (< 500 kg) surcharge | +10% ~ +30% | +8% ~ +25% | +15% ~ +40% | +15% ~ +45% | Small quantity, urgent delivery, or aerospace-certified lots increase cost. |