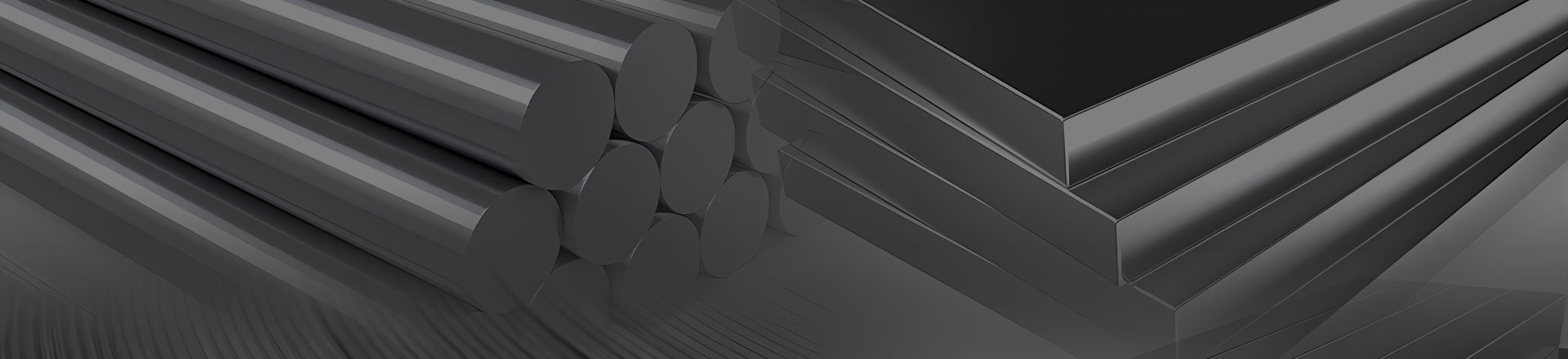

Nimonic 80A Round Bars

- Diameter:1 mm (0.0394 in) – 450 mm (17.717 in)

- Length:Up to 12 meters (472.441 in)

- Delivery Condition:Solution treated, annealed, age-hardened

- Surface Condition:Black, polished, turned, ground

- Shape:Round, square, hexagonal

E-mail:[email protected]

We’re here to help:Easy ways to get the answers you needNimonic 80A Round Bars

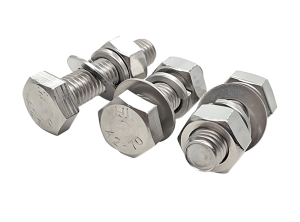

DescriptionNimonic 80A round bar is a nickel-chromium alloy reinforced with titanium, aluminum, and carbon, designed for excellent high-temperature strength and oxidation resistance. This alloy maintains outstanding mechanical properties and stability up to around 815°C (1500°F), making it ideal for demanding environments such as turbine blades, exhaust valves, fasteners, and heat-resistant components.

Thanks to its balanced composition and controlled heat treatment, Nimonic 80A exhibits superior creep and rupture strength, as well as excellent corrosion resistance in oxidizing and high-stress atmospheres. It also provides good machinability and weldability when proper procedures are followed, allowing for reliable performance in aerospace, power generation, and chemical industries.

We supply Nimonic 80A round bars in various diameters, lengths, and tolerances according to customer requirements, ensuring consistent quality and precision for every application.

Nimonic 80A Round Bars

Chemical Compositions| Carbon (C) | 0.10 % max. |

| Chromium (Cr) | 18.0-21.0 % |

| Silicon (Si) | 1.0 % max |

| Copper (Cu) | 0.2 % max. |

| Iron (Fe) | 3.0 % max. |

| Manganese (Mn) | 1.0 % max. |

| Titanium (Ti) | 1.8-2.7 % |

| Aluminum (Al) | 1.0-1.8 % |

| Cobalt (Co) | 2.0 % max. |

| Boron (B) | 0.008 % max. |

| Zirconium (Zr) | 0.15 % max. |

| Lead (Pb) | 0.0025 % max. |

| Sulfur (S) | 0.015 % max. |

| Nickel (Ni) | Balance |

Nimonic 80A Round Bars

Prices| Specification (Diameter) | China (USD/kg) | India (USD/kg) | Europe (USD/kg) | USA (USD/kg) | Remarks |

|---|---|---|---|---|---|

| Small Diameter ≤ 20 mm (Cold Drawn / Precision Ground) | 85 – 105 | 90 – 115 | 100 – 130 | 105 – 135 | High precision; suitable for aerospace, chemical, and high-temperature applications. |

| Medium Diameter 21 – 50 mm (Hot Rolled / Forged) | 75 – 95 | 80 – 105 | 95 – 125 | 100 – 130 | Common industrial sizes; pricing influenced by batch quantity and delivery time. |

| Large Diameter ≥ 51 mm (Heavy Forged) | 70 – 90 | 75 – 105 | 95 – 130 | 105 – 140 | Used for structural or chemical components; larger sizes reduce unit price but increase total cost. |

| Small Batch (< 500 kg) Surcharge | +10% ~ +30% | +8% ~ +25% | +15% ~ +40% | +15% ~ +45% | Prototype, small quantity, or urgent delivery orders add additional cost. |