Nimonic 90 is a high-performance nickel-based superalloy widely used in aerospace, power generation, and high-temperature industrial applications due to its exceptional strength, creep resistance, and oxidation resistance. Finding reliable Nimonic 90 suppliers is crucial for manufacturers and engineers who require consistent quality and timely delivery of this specialized material. In this article, we will explore the main suppliers, supply considerations, product forms, and key specifications of Nimonic 90 to help buyers make informed decisions.

Top Nimonic 90 Suppliers

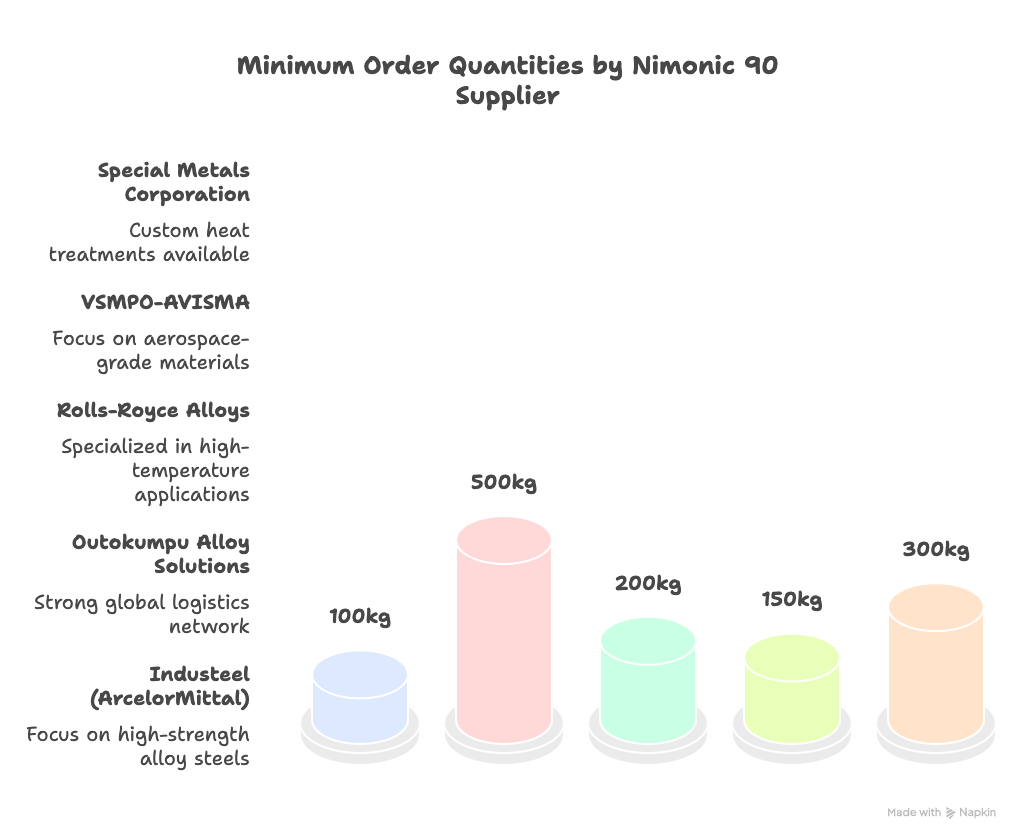

Several suppliers around the world provide Nimonic 90 in various forms. These suppliers are renowned for quality control, global shipping capabilities, and technical support.

| Fornecedor | País | Formulários de produtos | QUANTIDADE MÁXIMA DE ENCOMENDA | Special Notes |

|---|---|---|---|---|

| Corporação de Metais Especiais | EUA | Sheets, Plates, Bars, Tubes | 100 kg | Custom heat treatments available |

| VSMPO-AVISMA | Russia | Bars, Forgings, Rings | 500 kg | Focus on aerospace-grade materials |

| Rolls-Royce Alloys | REINO UNIDO | Sheets, Strips, Rings | 200 kg | Specialized in high-temperature applications |

| Outokumpu Alloy Solutions | Finlândia | Sheets, Plates, Tubes | 150 kg | Strong global logistics network |

| Industeel (ArcelorMittal) | França | Plates, Sheets, Forged Bars | 300 kg | Focus on high-strength alloy steels |

Nimonic 90 Material Forms

Nimonic 90 is available in multiple forms depending on the application requirements. Each form has specific characteristics suitable for particular industries.

| Formulário | Tamanhos típicos | Aplicações |

|---|---|---|

| Folha | 0.5 – 20 mm thickness | Aerospace turbine components, heat exchangers |

| Prato | 20 – 150 mm thickness | Industrial gas turbines, high-temperature structural components |

| Bar | 10 – 200 mm diameter | Shafts, bolts, and high-stress components |

| Tubo | Outer diameter 10 – 300 mm | Heat exchangers, piping in power plants |

| Forjamentos | Tamanhos personalizados | Aerospace engine parts, critical load-bearing components |

Composição química do Nimonic 90

The chemical composition ensures high strength, oxidation resistance, and stability at elevated temperatures. Buyers should always verify composition with suppliers for specific requirements.

| Elemento | Percentage (wt%) |

|---|---|

| Níquel (Ni) | 56 – 60 |

| Cobalto (Co) | 10 - 15 |

| Crómio (Cr) [European] | 18 – 22 |

| Titânio (Ti) | 2 – 3 |

| Alumínio (Al) | 1.8 – 2.5 |

| Carbono (C) | 0.08 - 0.15 |

| Molibdênio (Mo) | 0.5 – 1.0 |

Key Mechanical Properties

Nimonic 90 exhibits remarkable mechanical properties suitable for high-temperature applications. The following table summarizes its typical performance metrics.

| Imóveis | Valor |

|---|---|

| Resistência à tração final | 850 – 1000 MPa |

| Limite de escoamento | 500 – 650 MPa |

| Alongamento | 10 – 15% |

| Creep Resistance (1000°C, 1000h) | 0.2% strain |

| Hardness (HB) | 210 – 250 |

Supply Considerations

When sourcing Nimonic 90, buyers should consider minimum order quantities, lead times, quality certifications, and global shipping capabilities. Certification such as ISO 9001, EN 10204, and aerospace approvals (e.g., AS9100) ensures material reliability.

| Fator | Considerações |

|---|---|

| QUANTIDADE MÁXIMA DE ENCOMENDA | Ranges from 100 kg to 500 kg depending on supplier |

| Prazo de execução | 2 – 12 weeks based on product form and customization |

| Certificações | ISO, EN, AS9100, proprietary heat treatment certifications |

| Shipping | Global delivery with packaging for corrosion protection |

Applications of Nimonic 90

The alloy is primarily used in high-temperature, high-stress environments. Its resistance to creep and oxidation makes it ideal for critical components.

| Indústria | Aplicação |

|---|---|

| Aeroespacial | Turbine blades, combustor liners, engine shafts |

| Produção de energia | Gas turbine components, heat exchangers, high-temperature valves |

| Industrial | Furnace components, chemical plant reactors, high-temperature tooling |

Quality and Testing

Reliable suppliers perform extensive testing including chemical analysis, mechanical testing, non-destructive examination, and heat treatment verification. Certificates of conformity are provided to ensure compliance with specifications.

| Tipo de teste | Objetivo |

|---|---|

| Análise química | Verify alloy composition |

| Tensile and Hardness Testing | Confirm mechanical properties |

| Non-Destructive Testing (NDT) | Detect internal flaws or cracks |

| Heat Treatment Verification | Ensure proper solution annealing or aging |

Ordering Tips

When ordering Nimonic 90, consider specifying:

- Product form (sheet, plate, bar, tube, forging)

- Exact dimensions and tolerances

- Required mechanical properties and heat treatment

- Certification requirements

- Expected delivery timeline

Perguntas relacionadas

What is the typical lead time for Nimonic 90?

Lead times usually range from 2 to 12 weeks depending on product form, supplier, and customization requirements.

Can Nimonic 90 be supplied as custom forgings?

Yes, most suppliers offer custom forgings with specific dimensions and mechanical property requirements, especially for aerospace applications.

Which industries most commonly use Nimonic 90?

Nimonic 90 is commonly used in aerospace, power generation, and high-temperature industrial applications due to its creep resistance and oxidation resistance.