Inconel tubing, known for its exceptional resistance to heat, oxidation, and corrosion, is widely used in aerospace, chemical processing, power generation, and marine applications. Due to its high nickel content, Inconel tubing must be sourced from trusted suppliers to ensure compliance with strict quality standards such as ASTM, ASME, or AMS specifications. This article provides an overview of top Inconel tubing suppliers, pricing ranges, and selection tips to help you find the right supplier for your needs.

Top Global Inconel Tubing Suppliers

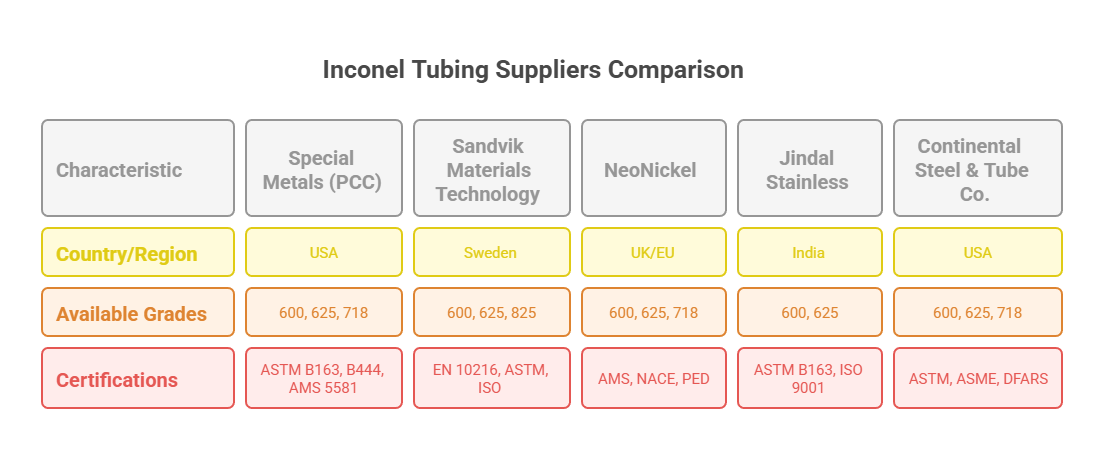

The following companies are recognized for supplying high-quality Inconel tubing, including grades like Inconel 600, 625, 718, and 825:

| Supplier | Country/Region | Available Grades | Certifications |

|---|---|---|---|

| Special Metals (PCC) | USA | 600, 625, 718 | ASTM B163, B444, AMS 5581 |

| Sandvik Materials Technology | Sweden | 600, 625, 825 | EN 10216, ASTM, ISO |

| NeoNickel | UK/EU | 600, 625, 718 | AMS, NACE, PED |

| Jindal Stainless | India | 600, 625 | ASTM B163, ISO 9001 |

| Continental Steel & Tube Co. | USA | 600, 625, 718 | ASTM, ASME, DFARS |

Inconel Tubing Types and Applications

Different Inconel grades are selected based on the application’s environment and operating temperature:

| Grade | Key Features | Applications |

|---|---|---|

| Inconel 600 | Oxidation and corrosion resistance, high temp strength | Furnace tubing, nuclear reactors |

| Inconel 625 | Excellent fatigue & seawater resistance | Offshore, chemical processing, aerospace |

| Inconel 718 | High strength, creep resistance, weldability | Gas turbines, engine tubing, cryogenic systems |

| Inconel 825 | Strong resistance to sulfuric & phosphoric acid | Acid production, heat exchangers |

Estimated Inconel Tubing Prices by Size

Prices for Inconel tubing depend on size, grade, finish, and order volume. Below is a pricing estimate for seamless Inconel tubing:

| Tube OD (inches) | Wall Thickness | Grade | Approx. Price per ft (USD) |

|---|---|---|---|

| 1/4″ | 0.035″ | Inconel 625 | $25 – $40 |

| 1/2″ | 0.049″ | Inconel 600 | $35 – $55 |

| 1″ | 0.065″ | Inconel 718 | $60 – $90 |

| 2″ | 0.083″ | Inconel 825 | $85 – $120 |

How to Choose the Right Inconel Tubing Supplier

When evaluating suppliers, consider the following criteria:

• Certifications: Ensure they meet ASTM, ASME, NACE, or PED standards depending on your project.

• Stock Availability: Check if they maintain ready stock for your size and grade.

• Cutting and Customization: Look for vendors who offer cut-to-length and special finishes.

• Origin and Compliance: For aerospace or defense, check for DFARS compliance and US/EU origin.

• Lead Times: Confirm production and shipping timelines, especially for large or custom orders.

Related Questions

What grades of Inconel tubing are most commonly used?

The most commonly used grades are Inconel 600 (oxidation resistance), Inconel 625 (marine and chemical use), and Inconel 718 (aerospace and high strength).

Can I buy Inconel tubing in small quantities?

Yes, many suppliers such as NeoNickel, Magellan Metals, and online distributors offer small-quantity sales and even cut-to-length services for Inconel tubing.

Where can I find DFARS-compliant Inconel tubing suppliers?

U.S.-based suppliers like Continental Steel, TW Metals, and Special Metals offer DFARS-compliant Inconel tubing suitable for defense and aerospace applications.