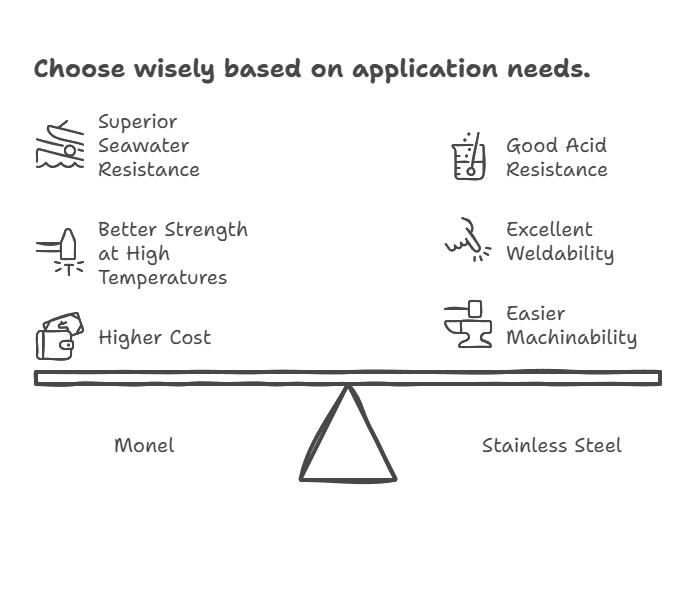

Monel and stainless steel are both widely used corrosion-resistant metal alloys, but they differ significantly in chemical composition, strength, resistance to specific environments, and cost. Choosing between Monel and stainless steel depends on your specific application—such as exposure to seawater, high temperatures, acids, or structural stress. This article compares Monel and stainless steel side by side to help you select the most suitable material.

Chemical Composition: Nickel vs. Iron Base

The most fundamental difference between Monel and stainless steel is their base elements. Monel is primarily a nickel-copper alloy, while stainless steel is an iron-based alloy with chromium.

| Alloy | Main Elements | Typical Grades |

|---|---|---|

| Monel | 65–70% Nickel, 20–29% Copper, Iron, Manganese | Monel 400, Monel K-500 |

| Stainless Steel | 60–75% Iron, 16–26% Chromium, Nickel, Molybdenum | 304, 316, 321, 410, 904L |

Corrosion Resistance Comparison

Both alloys are known for corrosion resistance, but Monel performs better in highly aggressive and marine environments.

| Property | Monel | Stainless Steel |

|---|---|---|

| Seawater Resistance | Excellent (even in flowing seawater) | Good (316 and 904L grades) |

| Acid Resistance | Excellent for hydrofluoric, sulfuric, and hydrochloric acids | Varies by grade; 316 good for acetic and citric acids |

| Stress Corrosion Cracking | Resistant | Susceptible in chloride environments |

| Oxidation Resistance | Moderate | Very good, especially at high temperatures |

Mechanical Properties and Strength

Monel generally offers better strength at room and elevated temperatures than many stainless steels.

| Property | Monel 400 | Stainless 316 |

|---|---|---|

| Tensile Strength (MPa) | 480–620 MPa | 515–620 MPa |

| Yield Strength (MPa) | 170–275 MPa | 205–290 MPa |

| Hardness (Brinell) | 135–200 | 150–217 |

| Density (g/cm³) | 8.8 | 7.9–8.0 |

Weldability and Machinability

Monel is more challenging to machine and weld than stainless steel due to its work-hardening properties.

| Aspect | Monel | Stainless Steel |

|---|---|---|

| Weldability | Good (requires filler and control) | Excellent (especially 304/316) |

| Machinability | Poor (work-hardens quickly) | Good (wide tool compatibility) |

Price Comparison: Monel vs Stainless Steel

Monel is significantly more expensive than stainless steel due to its high nickel content and more difficult processing.

| Material | Typical Price per Pound (USD) | Price Factor |

|---|---|---|

| Monel 400 | $20–$30/lb | 3x–5x stainless steel |

| Stainless Steel 316 | $3–$5/lb | Base pricing reference |

When to Use Monel or Stainless Steel

Select your alloy based on the severity of the environment, cost constraints, and design life expectations:

| Application | Recommended Alloy | Reason |

|---|---|---|

| Shipbuilding, Offshore Oil | Monel | Superior resistance to seawater and corrosion |

| Food Equipment, Architectural Use | Stainless Steel | Cost-effective, hygienic, corrosion-resistant |

| Acid Handling Systems | Monel | Exceptional acid resistance |

| Boilers, Heat Exchangers | Stainless Steel | High-temperature and oxidation resistance |

Related Questions

Is Monel better than stainless steel for marine use?

Yes, Monel offers superior corrosion resistance in seawater environments, making it better for marine use compared to stainless steel.

Why is Monel more expensive than stainless steel?

Monel is nickel-based (around 65–70%), and nickel is much more expensive than iron. It also requires more complex processing and alloying, which increases cost.

Can Monel rust like stainless steel?

No, Monel does not rust under normal conditions. It’s highly resistant to both rust and pitting, especially in chloride-rich or acidic environments, where stainless steel might corrode.