Nickel tube manufacturers supply high-performance tubing made from pure nickel or nickel-based alloys to industries such as aerospace, chemical processing, power generation, and marine engineering. These tubes are known for excellent corrosion resistance, heat resistance, and mechanical strength. With applications ranging from heat exchangers to condensers and fuel systems, the choice of manufacturer plays a key role in quality, compliance, and supply chain reliability.

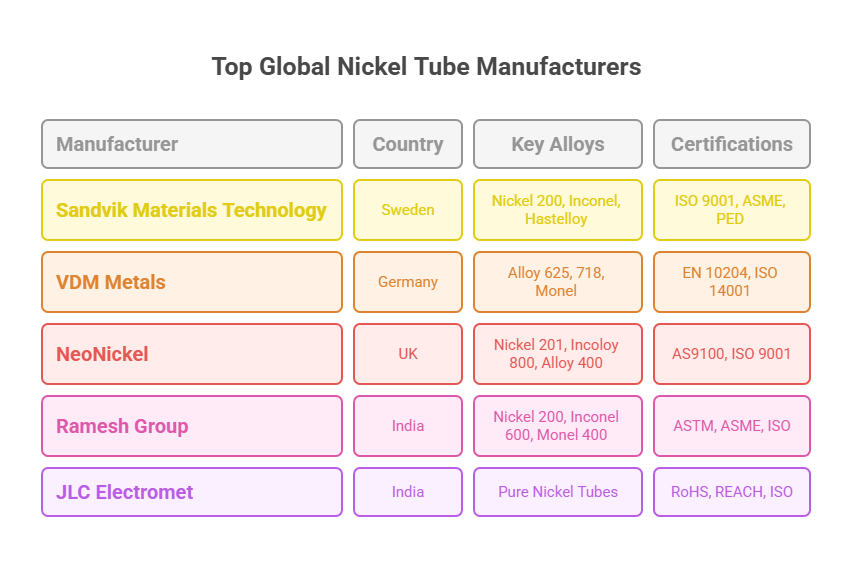

Top Global Nickel Tube Manufacturers

| Company | Country | Key Alloys | Certifications |

|---|---|---|---|

| Sandvik Materials Technology | Sweden | Nickel 200, Inconel, Hastelloy | ISO 9001, ASME, PED |

| VDM Metals (Part of Acerinox) | Germany | Alloy 625, 718, Monel | EN 10204, ISO 14001 |

| NeoNickel | UK | Nickel 201, Incoloy 800, Alloy 400 | AS9100, ISO 9001 |

| Ramesh Group | India | Nickel 200, Inconel 600, Monel 400 | ASTM, ASME, ISO |

| JLC Electromet | India | Pure Nickel Tubes | RoHS, REACH, ISO |

Common Nickel Tube Grades and Their Uses

| Grade | Composition | Applications |

|---|---|---|

| Nickel 200 | 99.6% pure nickel | Food processing, electronics, alkali handling |

| Nickel 201 | Low carbon variant of Nickel 200 | High-temperature electrical equipment |

| Inconel 600 | Nickel-Chromium alloy | Nuclear reactors, heat exchangers |

| Monel 400 | Nickel-Copper alloy | Marine systems, oil refining |

| Hastelloy C276 | Nickel-Molybdenum-Chromium alloy | Chemical processing, waste treatment |

Manufacturing Processes Used by Nickel Tube Suppliers

Seamless Tube Manufacturing: Involves piercing a billet followed by cold drawing or pilgering. Seamless tubes have superior integrity and pressure tolerance.

Welded Tube Production: Starts from nickel alloy strip or sheet, formed and TIG/laser welded. Cost-effective and suitable for lower-pressure applications.

Annealing and Pickling: Heat treatment to restore ductility, followed by surface cleaning to remove scale and oxides.

Non-Destructive Testing (NDT): Includes ultrasonic testing, eddy current testing, and hydrostatic testing for quality assurance.

Certifications to Look for in Nickel Tube Manufacturers

| Certification | Importance |

|---|---|

| ISO 9001 | Quality management system compliance |

| ASME / ASTM | Engineering and material standards for piping |

| PED 2014/68/EU | Pressure Equipment Directive for EU |

| NACE MR0175 | Use in sour gas environments |

| EN 10204 3.1 / 3.2 | Material test certification and traceability |

Applications Driving Global Demand for Nickel Tubes

Chemical Processing: Nickel tubing withstands sulfuric, hydrochloric, and hydrofluoric acids. Essential in reactors and evaporators.

Aerospace & Defense: Used in jet engine components, hydraulic lines, and heat shielding due to heat and corrosion resistance.

Power Generation: Heat exchanger and boiler tubes in nuclear and thermal power plants are commonly made from nickel alloys.

Marine Engineering: Monel and Inconel tubes resist seawater and are used in desalination and submarine systems.

How to Select a Reliable Nickel Tube Manufacturer

1. Product Range: Choose manufacturers offering both seamless and welded options in various nickel alloys.

2. Certifications: Prioritize ISO, ASTM, PED, and NACE-certified suppliers for compliance and traceability.

3. Technical Support: Reliable manufacturers offer documentation, CAD drawings, and third-party testing services.

4. Delivery Time: Evaluate stock availability, production lead time, and logistics capability, especially for overseas sourcing.

5. Customization: Check if the manufacturer can produce non-standard sizes, surface finishes, or cut-to-length tubes.

Frequently Asked Questions

Who are the top manufacturers of nickel tubes?

Leading manufacturers include Sandvik (Sweden), VDM Metals (Germany), NeoNickel (UK), Ramesh Group (India), and JLC Electromet (India). These companies produce high-quality seamless and welded nickel tubes for global markets.

What types of nickel tubes are available?

Manufacturers offer pure nickel tubes (Nickel 200/201) and nickel alloy tubes (Inconel, Monel, Hastelloy) in both seamless and welded forms, depending on the required mechanical and corrosion properties.

How can I verify the quality of nickel tube manufacturers?

Check for certifications like ISO 9001, ASME/ASTM compliance, and PED. Also request mill test reports (MTRs), inspect NDT results, and confirm the manufacturer’s ability to meet project specifications and lead times.