Our Nickel Alloy Seamless Tubes & Pipes are manufactured to provide exceptional mechanical strength, excellent corrosion resistance, and superior thermal stability. These seamless tubes and pipes are ideal for high-performance applications in industries such as aerospace, chemical processing, petrochemical, and marine engineering, where reliability and durability are critical.

We offer a wide selection of nickel alloy seamless pipes and tubes in premium materials like Inconel 625, Inconel 718, Monel 400, Hastelloy C-276, C22, Nickel 200, 201, and Alloy 825. These seamless tubes are produced to meet rigorous industry standards and offer outstanding resistance to high temperatures, corrosion, and oxidation, making them perfect for use in extreme environments.

Our nickel alloy seamless pipes are available in a variety of sizes and specifications, including ASTM B163, ASTM B166, and ASME SB163, ensuring compatibility with various industrial applications. Whether you require tubes for heat exchangers, boilers, or chemical reactors, our seamless nickel alloy tubes deliver exceptional quality and performance.

Looking for a trusted nickel alloy tubing supplier? Contact us today for competitive prices, quick delivery, and full product certification for all our nickel alloy seamless tubes & pipes.

We offer a wide range of Seamless Tubes & Pipes, customizable to meet customer requirements

| Parameter | Specification Range |

|---|---|

| Seamless Pipe Outer Diameter | 6 mm (0.236 in) – 500 mm (19.685 in) |

| Capillary Tube Outer Diameter | 0.2 mm (0.0079 in) – 6 mm (0.236 in) |

| Wall Thickness | 0.05 mm (0.00197 in) – 40 mm (1.575 in) |

| Single Tube Length | Up to 12 meters (472.441 in) |

| Coil Tube Length | Up to 150 meters (5905.511 in) |

| Delivery Condition | Solution Annealed, Annealed, Age-Hardened |

| Surface Condition | Pickled, Sandblasted, Polished, BA, EP |

We offer a variety of nickel-based alloy seamless tubes that meet different industry standards and application requirements

Nickel alloys, with their excellent performance, are widely used in various harsh environments, meeting the special requirements of different industries

Nickel alloys are used in chemical equipment for their excellent corrosion resistance, strength, and durability, making them ideal for components like reactors, heat exchangers, and piping systems.

More

Nickel alloys are used in marine engineering for their corrosion resistance and strength, ideal for ship parts and offshore platforms.

More

Nickel alloys are used in aerospace for their high strength, heat resistance, and durability, making them perfect for engine components and structural parts.

More

Nickel alloys are used in semiconductors for their conductivity and resistance to corrosion, making them ideal for connectors and heat sinks.

More

Nickel alloys are used in the medical field for their biocompatibility, corrosion resistance, and strength, making them suitable for implants and surgical instruments.

More

Nickel alloys are used in the oil and gas industry for their resistance to corrosion, high strength, and ability to withstand extreme temperatures, making them ideal for drilling equipment, pipelines, and offshore platforms.

MoreNickel alloy seamless pipes provide reliable solutions for various demanding environments with their excellent performance

Maintains excellent corrosion resistance in environments with strong acids and alkalis, extending equipment lifespan

Maintains good mechanical properties and structural stability at extreme temperatures up to 1100°C

Excellent mechanical strength and toughness enable it to withstand high-pressure environments and mechanical stress, ensuring system safety

Outstanding durability significantly reduces maintenance frequency and replacement costs, enhancing overall system economy

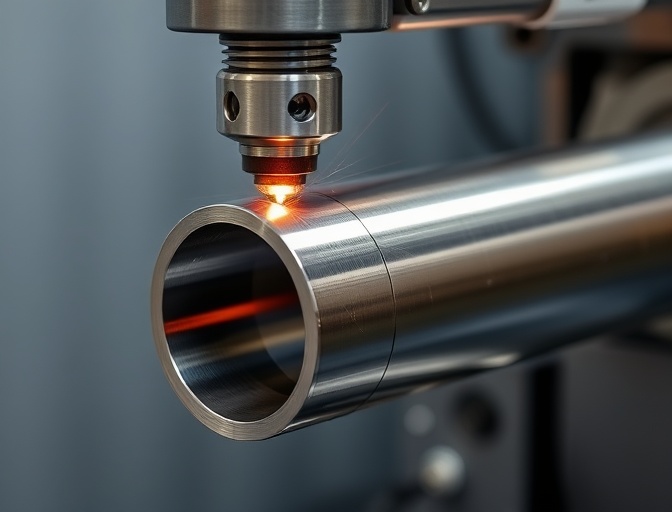

We offer comprehensive processing and customization services to meet your specific requirements

We provide precise cutting services with tolerance controlled within ±1mm to meet your exact installation requirements

We provide professional Positive Material Identification (PMI) testing to ensure material composition meets standard requirements

We offer professional end treatments such as chamfering, beveling, and flaring to meet welding and connection needs

We support small batch customization and sampling to help clients verify design and material suitability

We’ve compiled common customer questions to help you better understand our products and services

Our nickel alloy seamless tubes and pipes are widely used in chemical processing, power generation, aerospace, marine, and heat exchanger systems due to their excellent corrosion resistance and high-temperature strength.

We conduct rigorous quality control including eddy current testing, hydrostatic pressure testing, ultrasonic inspection, and detailed dimensional checks. All products come with Mill Test Certificates for full traceability.

Yes, nickel alloys are specifically designed for extreme environments. They offer exceptional resistance to oxidation, acids, and chlorides, making them ideal for harsh industrial conditions.

We provide complete documentation, including Mill Test Certificates (EN 10204 3.1/3.2), packing lists, invoices, heat numbers, and third-party inspection reports if requested.

Yes, we have experience in international logistics and can provide all necessary documents such as the Certificate of Origin, commercial invoice, packing list, and any special certificates required by the destination country.