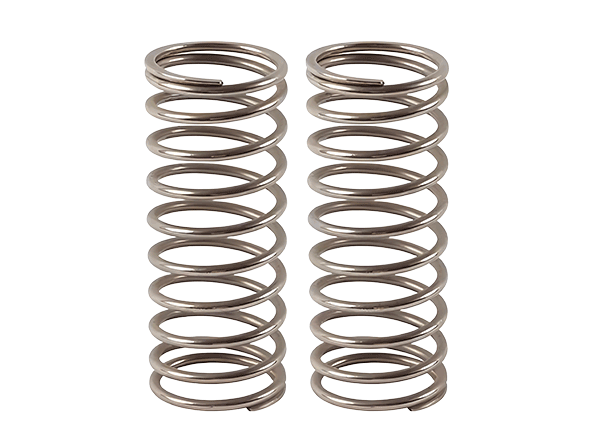

We manufacture and supply high-performance Nickel Alloy Springs engineered for extreme environments where corrosion resistance, high temperature strength, and fatigue resistance are essential. These corrosion-resistant springs are widely used in aerospace, power generation, oil & gas, marine, chemical processing, and high-temperature industrial applications.

Our spring materials include premium-grade nickel alloys such as Inconel X-750, Inconel 718, Monel 400, Hastelloy C276, and Nickel 200. We offer compression springs, tension springs, torsion springs, and wire forms, all made from precision-drawn nickel spring wire that meets stringent international standards.

These nickel alloy springs offer excellent performance in high-stress and high-temperature conditions, making them ideal for valves, turbines, downhole tools, electrical contacts, and corrosive fluid systems. All components are available in custom sizes, heat treatments, and surface finishes to match your application.

Looking for reliable Inconel spring suppliers or sourcing nickel-based alloy spring wire for your next project? Contact us today for specifications, material certifications, and competitive pricing.

We offer a wide range of Springs, customizable to meet customer requirements

| Parameter | Specification Range |

|---|---|

| Wire Diameter | 0.1 mm (0.0039 in) – 15 mm (0.5906 in) |

| Inner Diameter | 1 mm (0.0394 in) – 200 mm (7.874 in) |

| Outer Diameter | 2 mm (0.0787 in) – 250 mm (9.843 in) |

| Free Length | 5 mm (0.1969 in) – 500 mm (19.685 in) |

| Total Number of Turns | 3-50 turns |

We offer a variety of nickel-based alloy seamless tubes that meet different industry standards and application requirements

Nickel alloys, with their excellent performance, are widely used in various harsh environments, meeting the special requirements of different industries

Nickel alloys are used in chemical equipment for their excellent corrosion resistance, strength, and durability, making them ideal for components like reactors, heat exchangers, and piping systems.

More

Nickel alloys are used in marine engineering for their corrosion resistance and strength, ideal for ship parts and offshore platforms.

More

Nickel alloys are used in aerospace for their high strength, heat resistance, and durability, making them perfect for engine components and structural parts.

More

Nickel alloys are used in semiconductors for their conductivity and resistance to corrosion, making them ideal for connectors and heat sinks.

More

Nickel alloys are used in the medical field for their biocompatibility, corrosion resistance, and strength, making them suitable for implants and surgical instruments.

More

Nickel alloys are used in the oil and gas industry for their resistance to corrosion, high strength, and ability to withstand extreme temperatures, making them ideal for drilling equipment, pipelines, and offshore platforms.

MoreNickel alloy seamless pipes provide reliable solutions for various demanding environments with their excellent performance

Maintains excellent corrosion resistance in environments with strong acids and alkalis, extending equipment lifespan

Maintains good mechanical properties and structural stability at extreme temperatures up to 1100°C

Excellent mechanical strength and toughness enable it to withstand high-pressure environments and mechanical stress, ensuring system safety

Outstanding durability significantly reduces maintenance frequency and replacement costs, enhancing overall system economy

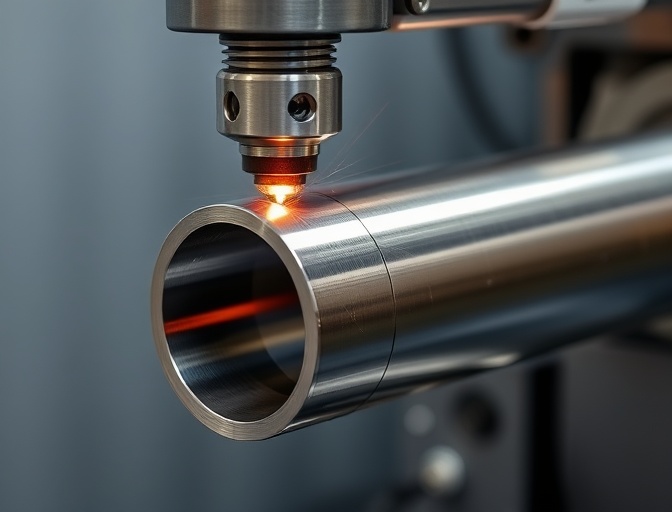

We offer comprehensive processing and customization services to meet your specific requirements

We provide precise cutting services with tolerance controlled within ±1mm to meet your exact installation requirements

We provide professional Positive Material Identification (PMI) testing to ensure material composition meets standard requirements

We offer professional end treatments such as chamfering, beveling, and flaring to meet welding and connection needs

We support small batch customization and sampling to help clients verify design and material suitability

We’ve compiled common customer questions to help you better understand our products and services

Nickel alloy springs are commonly used in aerospace, automotive, oil & gas, and marine industries due to their excellent fatigue resistance, corrosion resistance, and ability to perform under high temperatures and harsh environments.

We perform a variety of mechanical tests, including tensile strength, fatigue testing, and spring set measurements to ensure the springs meet required performance specifications. Additionally, we conduct stress relaxation tests to verify the springs' ability to maintain force over time.

Yes, we offer custom spring manufacturing services. Whether you need specific dimensions, shapes, or material grades, we can produce springs tailored to your exact requirements.

Yes, we provide Mill Test Certificates (MTC) for every batch of springs, which include chemical composition, mechanical properties, and heat treatment details. Third-party inspections can also be arranged as per customer requirements.

Nickel alloy springs are carefully packaged in protective wrapping to prevent corrosion and damage. Springs are typically placed in sturdy boxes or cartons, and we use foam padding or other materials to ensure they remain secure during transport.