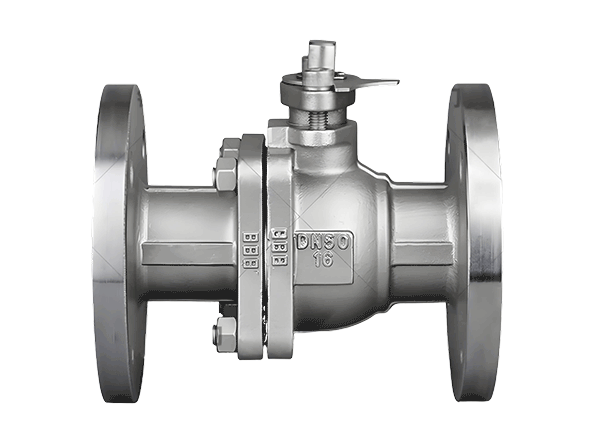

Our Nickel Alloy Valves are designed for critical applications in harsh and corrosive environments, offering outstanding resistance to acids, alkalis, and high-temperature oxidation. We supply a wide selection of industrial valves made from high-performance nickel-based alloys, including Inconel valves, Monel valves, Hastelloy valves, Nickel 200 valves, and Alloy 20 valves.

Common grades include Inconel 625 and 718, Monel 400 and K500, Hastelloy C276 and C22, Nickel 200/201, and Alloy 20. These corrosion-resistant valves are widely used in the chemical industry, offshore platforms, marine systems, power generation, and oil & gas operations.

We offer a complete range of valve types, such as gate valves, globe valves, ball valves, check valves, and pressure relief valves, all manufactured to international standards such as ASTM, ASME, and API. Our nickel alloy valves are available in various pressure ratings, end connections, and sizes to suit your project needs.

Looking for reliable nickel alloy valve suppliers or corrosion-resistant valve solutions? Contact us today for technical support or a customized quote for your specific application.

We offer a wide range of Valves, customizable to meet customer requirements

| Parameter | Specification Range |

|---|---|

| Gate Valve | Up to 60 inches (approx. 1.5 meters) |

| Ball Valve | Up to 72 inches (approx. 1.8 meters) |

| Butterfly Valve | Up to 200 inches (approx. 5 meters) |

| Globe Valve | Up to 48 inches (approx. 1.2 meters) |

| Plug Valve | Up to 24 inches (approx. 0.6 meters) |

| Check Valve | Up to 72 inches (approx. 1.8 meters) |

| Surface Finish | Sandblasted, Bright |

We offer a variety of nickel-based alloy seamless tubes that meet different industry standards and application requirements

Nickel alloys, with their excellent performance, are widely used in various harsh environments, meeting the special requirements of different industries

Nickel alloys are used in chemical equipment for their excellent corrosion resistance, strength, and durability, making them ideal for components like reactors, heat exchangers, and piping systems.

More

Nickel alloys are used in marine engineering for their corrosion resistance and strength, ideal for ship parts and offshore platforms.

More

Nickel alloys are used in aerospace for their high strength, heat resistance, and durability, making them perfect for engine components and structural parts.

More

Nickel alloys are used in semiconductors for their conductivity and resistance to corrosion, making them ideal for connectors and heat sinks.

More

Nickel alloys are used in the medical field for their biocompatibility, corrosion resistance, and strength, making them suitable for implants and surgical instruments.

More

Nickel alloys are used in the oil and gas industry for their resistance to corrosion, high strength, and ability to withstand extreme temperatures, making them ideal for drilling equipment, pipelines, and offshore platforms.

MoreNickel alloy seamless pipes provide reliable solutions for various demanding environments with their excellent performance

Maintains excellent corrosion resistance in environments with strong acids and alkalis, extending equipment lifespan

Maintains good mechanical properties and structural stability at extreme temperatures up to 1100°C

Excellent mechanical strength and toughness enable it to withstand high-pressure environments and mechanical stress, ensuring system safety

Outstanding durability significantly reduces maintenance frequency and replacement costs, enhancing overall system economy

We offer comprehensive processing and customization services to meet your specific requirements

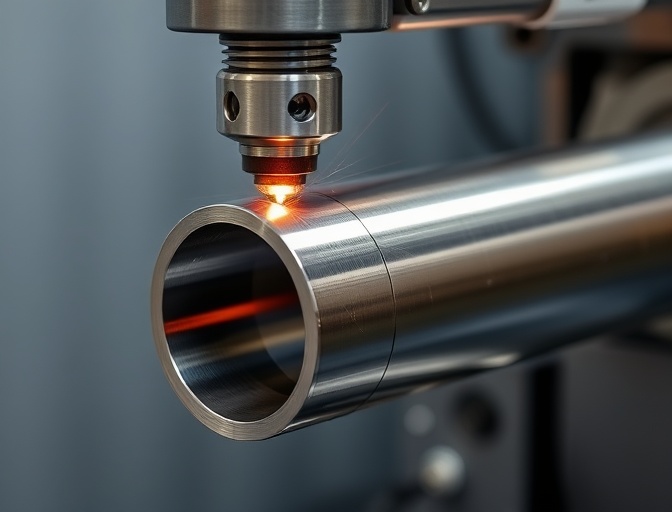

We provide precise cutting services with tolerance controlled within ±1mm to meet your exact installation requirements

We provide professional Positive Material Identification (PMI) testing to ensure material composition meets standard requirements

We offer professional end treatments such as chamfering, beveling, and flaring to meet welding and connection needs

We support small batch customization and sampling to help clients verify design and material suitability

We’ve compiled common customer questions to help you better understand our products and services

Nickel alloy valves are widely used in chemical processing, offshore platforms, power plants, and marine environments. They are ideal for handling corrosive fluids, high-pressure steam, and extreme temperature conditions.

Nickel alloys provide excellent resistance to a wide range of corrosive substances including hydrochloric acid, sulfuric acid, and seawater. This makes them suitable for aggressive media and critical service conditions.

Each valve undergoes hydrostatic and pneumatic pressure testing, along with visual inspection and dimensional checks. We also test for seat leakage and sealing integrity to ensure reliable operation.

Yes, our nickel alloy valves comply with standards such as API, ASME, ASTM, and DIN. We provide Mill Test Certificates (EN 10204 3.1) and can arrange third-party inspection if required.

Valves are securely wrapped in anti-corrosion materials, capped or plugged at openings, and packed in strong fumigated wooden crates. The packaging is designed to prevent damage and contamination during long-distance transport.