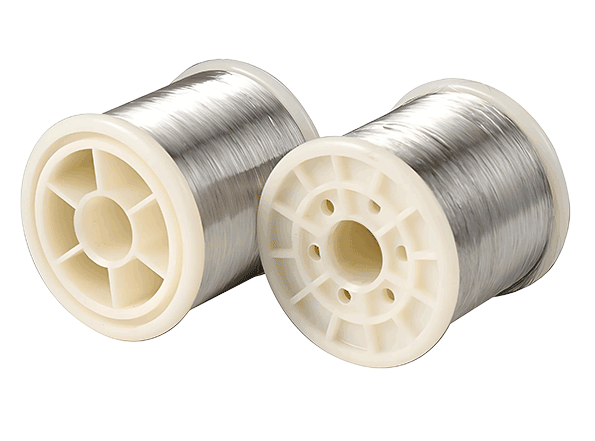

Our Nickel Alloy Wires are engineered for demanding industrial applications that require excellent corrosion resistance, high strength, and stability at extreme temperatures. We supply a wide range of nickel alloy wire products, including Inconel wire, Monel wire, Hastelloy wire, Alloy 20 wire, and Nickel 200 wire, available in various diameters and forms to meet your exact specifications.

Common grades we offer include Inconel 600, 625, and 718, Monel 400 and K500, Hastelloy C276 and C22, Nickel 200/201, and Alloy 20. These wires are widely used in aerospace, chemical processing, marine, electronics, and high-temperature furnace applications.

Whether you need corrosion-resistant nickel wire, nickel-based resistance wire, or nickel alloy heating wire for high-performance environments, our products provide reliable solutions. All materials are produced with tight quality control to ensure excellent mechanical properties and long-term durability.

We offer fast delivery and full technical support for custom orders, including drawn wire, spool wire, coil wire, and straight-cut lengths. Contact us today to request a quote or learn more about our full range of nickel alloy wires.

We offer a wide range of Wires, customizable to meet customer requirements

| Parameter | Specification Range |

|---|---|

| Diameter | 0.01 mm (0.00039 in) – 10 mm (0.3937 in) |

| Length | Customizable |

| Delivery Condition | Solution Annealed, Annealed, Full Hard, Half Hard, Age-Hardened |

| Surface Condition | Pickled, Polished, Cold Drawn Bright Surface |

We offer a variety of nickel-based alloy seamless tubes that meet different industry standards and application requirements

Nickel alloys, with their excellent performance, are widely used in various harsh environments, meeting the special requirements of different industries

Nickel alloys are used in chemical equipment for their excellent corrosion resistance, strength, and durability, making them ideal for components like reactors, heat exchangers, and piping systems.

More

Nickel alloys are used in marine engineering for their corrosion resistance and strength, ideal for ship parts and offshore platforms.

More

Nickel alloys are used in aerospace for their high strength, heat resistance, and durability, making them perfect for engine components and structural parts.

More

Nickel alloys are used in semiconductors for their conductivity and resistance to corrosion, making them ideal for connectors and heat sinks.

More

Nickel alloys are used in the medical field for their biocompatibility, corrosion resistance, and strength, making them suitable for implants and surgical instruments.

More

Nickel alloys are used in the oil and gas industry for their resistance to corrosion, high strength, and ability to withstand extreme temperatures, making them ideal for drilling equipment, pipelines, and offshore platforms.

MoreNickel alloy seamless pipes provide reliable solutions for various demanding environments with their excellent performance

Maintains excellent corrosion resistance in environments with strong acids and alkalis, extending equipment lifespan

Maintains good mechanical properties and structural stability at extreme temperatures up to 1100°C

Excellent mechanical strength and toughness enable it to withstand high-pressure environments and mechanical stress, ensuring system safety

Outstanding durability significantly reduces maintenance frequency and replacement costs, enhancing overall system economy

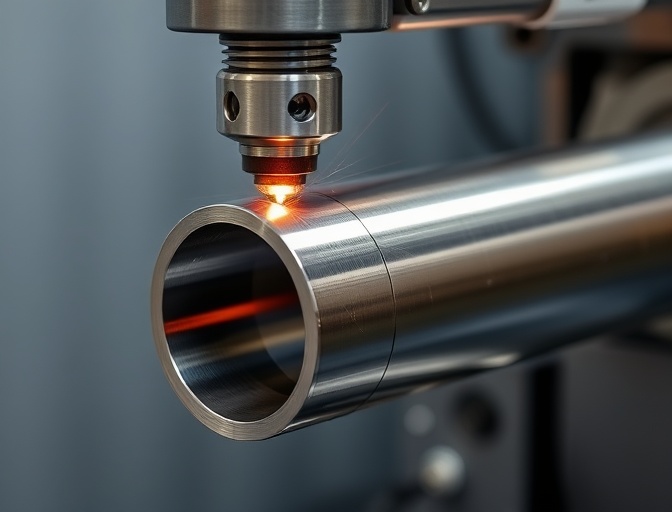

We offer comprehensive processing and customization services to meet your specific requirements

We provide precise cutting services with tolerance controlled within ±1mm to meet your exact installation requirements

We provide professional Positive Material Identification (PMI) testing to ensure material composition meets standard requirements

We offer professional end treatments such as chamfering, beveling, and flaring to meet welding and connection needs

We support small batch customization and sampling to help clients verify design and material suitability

We’ve compiled common customer questions to help you better understand our products and services

Nickel alloy wires are widely used in electronics, resistance heating, aerospace, chemical processing, medical devices, and welding filler materials due to their excellent electrical conductivity, heat resistance, and corrosion resistance.

Nickel alloy wires maintain strength and oxidation resistance even at elevated temperatures, making them ideal for use in heating elements, furnace components, and thermal sensors.

Yes, nickel alloy wires offer outstanding resistance to various corrosive environments, including acids, alkalis, seawater, and industrial gases. Alloys like Inconel, Hastelloy, and Monel are specifically designed for such conditions.

Absolutely. Our wires comply with ASTM, AMS, ISO, and DIN standards. Each order includes Mill Test Certificates (EN 10204 3.1) that list the chemical composition, mechanical properties, and heat number for traceability.

The wires are supplied on spools, coils, or cut lengths, then vacuum-sealed or wrapped in anti-corrosion film. They are packed in cartons or wooden cases with clear labeling to ensure safe delivery and easy identification.